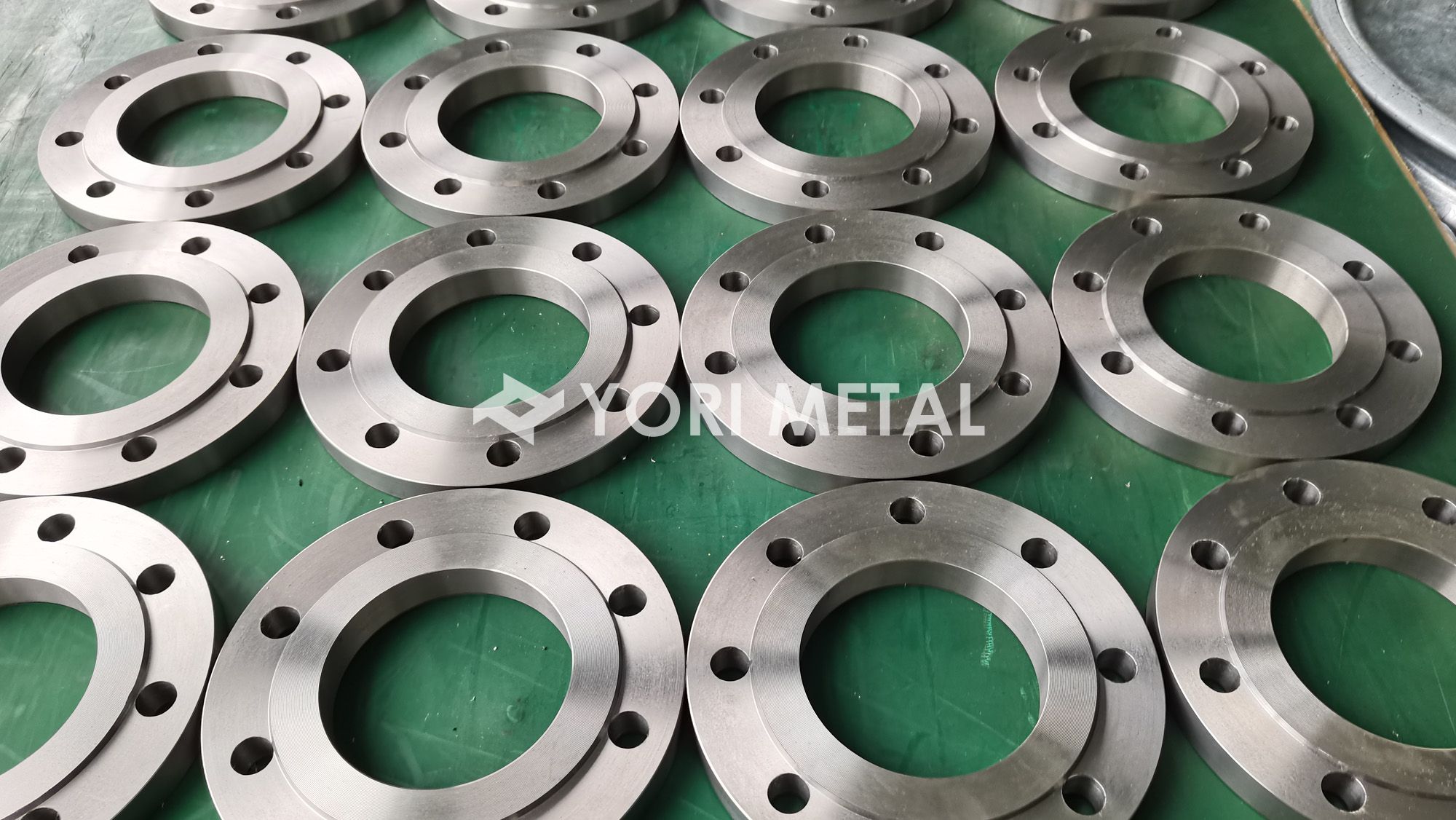

Three processing methods of titanium flange

Titanium flanges are widely used in chlor-alkali supply industry, petrochemical industry, pharmaceutical intermediates, fuel, electricity, salt making, aviation, shipbuilding, metallurgy and electrical machinery and other industries. Combining years of experience in the production and processing of titanium forgings, Yori Metal shares the processing methods of titanium flanges as follows:

1. Forging method

A part of the flange is punched out with a swaging machine to reduce the outer diameter.

2. Roller method

The core is placed in the center of the titanium flange, and the outside is pushed by rollers to perform round edge processing.

3. Stamping method

Use a tapered core to expand the titanium flange to the desired desired size and shape on a punch press.