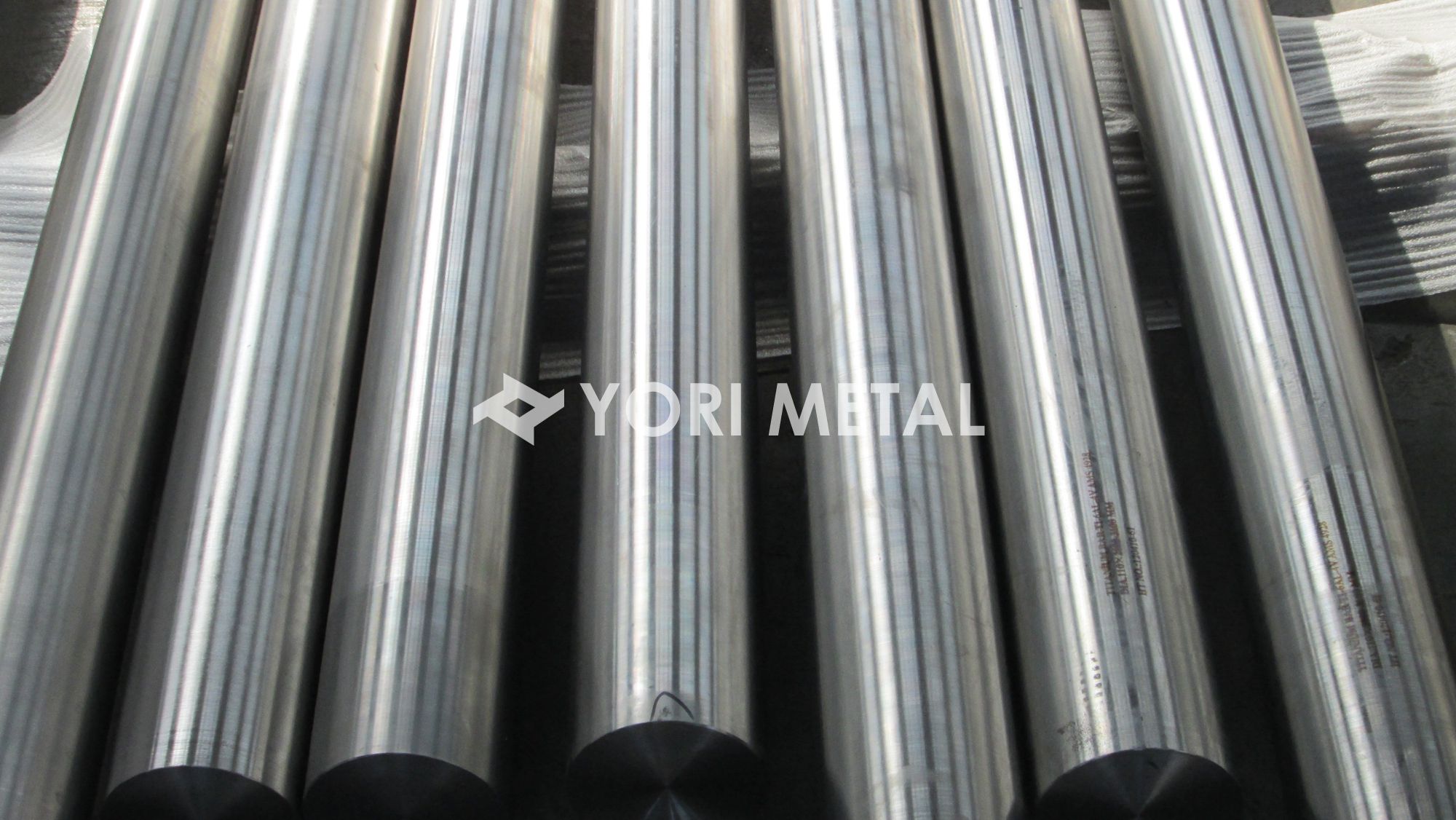

Titanium & titanium alloy wire & rod

1.Quick details

| Product Name | Titanium&titanium alloy wire&rod |

| Material | Pure titanium and Titanium alloy |

| Titanium Grade | GR1/GR2/GR3/Gr4/GR5/GR7/GR9/GR12/Gr5Eli/Gr23 ERTi-1/ERTi-2/ERTi-3/ERTi-4/ERTi-5Eli/ERTi-7/ERTi-9/ERTi-11/ERTi-12 Ti15333/Nitinol Alloy |

| Standard | AWS A5.16/ASTM B863/ASME SB863, ASTMF67, ASTM F136, ISO-5832-2(3) etc |

| Shape | Titanium Coil Wire/Titanium Spool Wire/Titanium Straight Wire/Titanium Straight rod&bar |

| Wire Gauge | Dia(0.03--500) *L |

| Process | Bar billets-hot rolling-drawing-annealing-strength-pickling |

| Surface | Polishing, picking, acid washed, black oxide |

| Main Technique | Hot Forged; Hot Rolled; Cold drawn; Straighten etc |

| Material Milling Certificate | According to. EN 10204.3.1 Including Chemical composition and Mechanical property |

| Application | Welding, Industry, Medical, Aerospace, Electronic etc |

2. Product introduction

1)Titanium wire is widely used in welding wire for equipment welding, titanium wire for glasses and other accessories, such as structural wire, woven mesh. As well as powder with dry 3D printer.

2)titanium alloy wire(Gr5) main scope of use: welding, screw nuts (Apple mobile phone with 2.42mmTitanium nut), as an elastic wire can be made into a bullet and other dry automobile motorcycle shock absorber or other bomb device, the advantages are light weight, high strength.