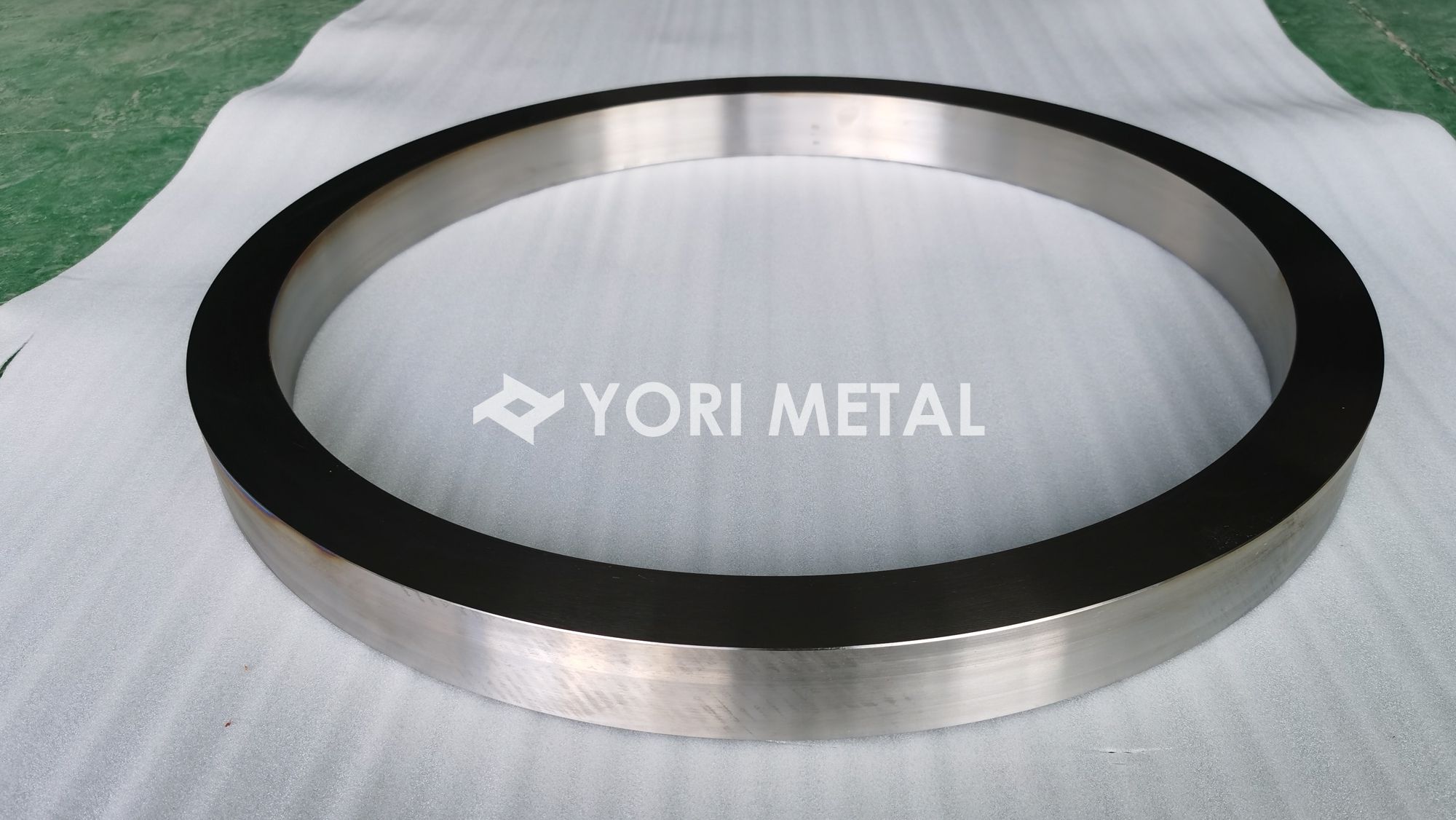

ASTM B381 gr2 gr5 titanium and titanium alloy forged blocks discs rings

Product Name: Titanium Ring

Surface: forged surface, rolled surface, car polished surface, polished surface.

Application areas: used in aerospace, medical, chemical, petrochemical, shipbuilding, electrolysis, electroplating and other industries.

The performance characteristics of titanium ring:

1) High strength

The density of titanium alloy is generally about 4.5g/cm3, which is only 60% of steel. The strength of pure titanium is close to that of ordinary steel. Some high-strength titanium alloys exceed the strength of many alloy structural steels. Therefore, the specific strength (strength/density) of titanium alloy is much greater than that of other metal structural materials, and parts and components with high unit strength, good rigidity and light weight can be produced. At present, titanium alloys are used in aircraft engine components, skeletons, skins, fasteners and landing gear.

2) High thermal strength

The operating temperature is several hundred degrees higher than that of aluminum alloys, and the required strength can still be maintained at moderate temperatures, and it can work for a long time at a temperature of 450 to 500 °C. The specific strength of aluminum alloy decreases significantly at 150 °C. The working temperature of titanium alloy can reach 500 ℃, and the working temperature of aluminum alloy is below 200 ℃.

3) Good corrosion resistance

Titanium alloy works in humid atmosphere and seawater medium, and its corrosion resistance is much better than that of stainless steel; its resistance to pitting corrosion, acid corrosion, and stress corrosion is particularly strong; it has strong resistance to alkali, chloride, chlorine, organic substances, nitric acid, etc. Excellent corrosion resistance. However, titanium has poor corrosion resistance to media with reducing oxygen and chromium salts.